More work on the Ed's today. It was finally time to tackle the hardest parts of the model; the ends.

The Ed has a rather complex shape at each end, that was once described as having all the aesthetic qualities of an upturned bathtub. The sloping fronts make it extremely difficult to get the windows square as they have to be a trapezoid in order to look square from the front. I would love to say that I sat down and let my inner finescaler calculate out all the measurements to several fractions of a millimeter. the rest of me said sod it, tied him the a chair out the back and started cutting. I started with a piece of paper that was the right height. The center window was measured out as well as the starting points for the inner corners of the larger windows. I then carefully shaped the bottom of the paper to the front of the Ed and carefully cut the paper back till it was a square fit. I then measured out where the outside of the windows would be and joined them up and cut it out with a very sharp knife. I used this as a template for the other 3. Yes, it was indeed a prick of a job. These were then glued into position with superglue. This operation is not for the faint hearted, slow witted, fumble fingered, or anyone with an allergy to superglue fumes (I qualify in several of these categories, though I'm not yet allergic). The edges were smoothed back with a file. I also added the cab sides without the doors.

The next fun job to tackle was the headlights. The Hutt built machines were fitted with a cowled headlight that looks beautiful. Its another one of those 'How can I make this harder for a modeler' bits. So, how does one turn up a cowled headlight without access to a lathe when the only thing one has that is the right diameter is a thick heavy bit of brass rod?

'I'm also playing the harmonica and banging a drum as well'

'I'm also playing the harmonica and banging a drum as well'A piece of brass rod is cut off and chucked up in the power drill. This is then clamped between the legs with one leg operating the trigger. The hands are then free to use a variety of files and hacksaw blades to do the shaping. I then used various grades of sandpaper to clean up the tool marks. The brass surprisingly doesn't generate much heat as its all being disipated by the drill chuck.

You will notice that I have not done anything to add a working light. This is just due to the fact that I find lighting beyond me. It always looks wrong and I can't seem to get it to work right. Its also one less thing to go wrong on the layout.

The base of the cowl then had to be shaped to fit the curved end of the cab. This was achieved using a large round file I have owned for 15 years especially for this task.

When I had removed enough brass I then glued it into position with superglue.

The second one was then finished using the same methods.

The Addington built machines just had a plain headlight. this was just cut out in the drill using a hacksaw. At least someone on the mainland was thinking straight.

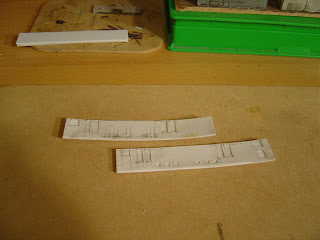

As you can see from these pictures I have also added the roof walks. I was not sure how wide to make them, and in the end made them 2.5mm (1' in scale) as that was the narrowest board I would have walked on at any height, let alone that height. I have also painted the outer roof and the windows. I have yet to actually glue the pantographs in as I'm just waiting on some pictures of the electric bits on the roof of 101 so that I can add that detail.

They do still look butt ugly