DB thinks:

Despite life and other bruises preventing me from generating massive dollops of progress, a few wee projects have made small steps forward.

Most interestingly, I'm making some moves on the trek towards Greymouth station now that work on Elmer Lane has slowed down. I'll probably build a steam-era sanding tower there, add some power poles and people, and have yet to decide whether to include a water vat or not, but most of the key bits that I wanted at the depot are more or less done.

So it is high time to start progressing in a northeastererly direction, as has been threatened for some time. This 'planning' (I really need a much looser word here) started in March, and since then, I've been daydreaming about where this might lead. A Greymouth Empire Module Set could easily include:

- 'a main line connection' to other people's modules (with Omoto bridge and loco dump)

- The wharf, with its hydraulic cranes serving colliers tied up for loading

- The wooden Cobden 'S' bridge across the Grey river

- (and on to Rewanui).

- (in hindsight, a turnout by the roundhouse could have given a Hokitika branch too!

|

| Greymouth modules concept (not all tracks shown) |

- design the yard throat module,

- at around the same time, link those yard tracks with Elmer lane using 'Greymouth station'

- build Omoto to provide a mainline module that can transition to other people's modules

- add the wharf for more operational fun

- Build the Cobden S bridge, because that would be really cool,

- and at the same time, build the Rewanui station/state coal mine terminus.

- build at least one Rewanui 'branch' connecting module between the bridge and Rewanui Station to provide a little more branchline running time and interest. The branch/bridge/incline etc wouldn't technically be 'mainline', so could have tighter curves and points than the usual, much steeper grades, and even a (low) centre rail for looks, which could be interesting. I doubt I would make Dunollie Junction (and the Rapahoe Branch) to slot in between the S bridge and the Rewanui branch, but someone else might!

The more 'interesting' module (from a Darryl perspective) is the next one - the yard throat, the tracks across Mawhera quay, the signal box, Riverside station, and the connections to the other future modules.

The design of this throat should obviously enable trains to come off the 'mainline' and go into the yard/staging tracks (perhaps reversing using the Elmer Lane roundhouse loop first).

It should allow 'Rewanui to Riverside' passenger or coal trains to operate without interfering with the core layout (the 'mainline'). This includes a runaround at Riverside station so it can be used even if the wharf or Rewanui modules never get built. Freight from Rewanui can be moved straight to the wharf yard, or into the Greymouth Yard. Passenger cars used on Rewanui trains might be stored in the Greymouth Station yard when not in use.

The wharf should also be operable fairly independently, without upsetting other operators. Its layout should allow trains to come to and from both Rewanui and from the mainline.

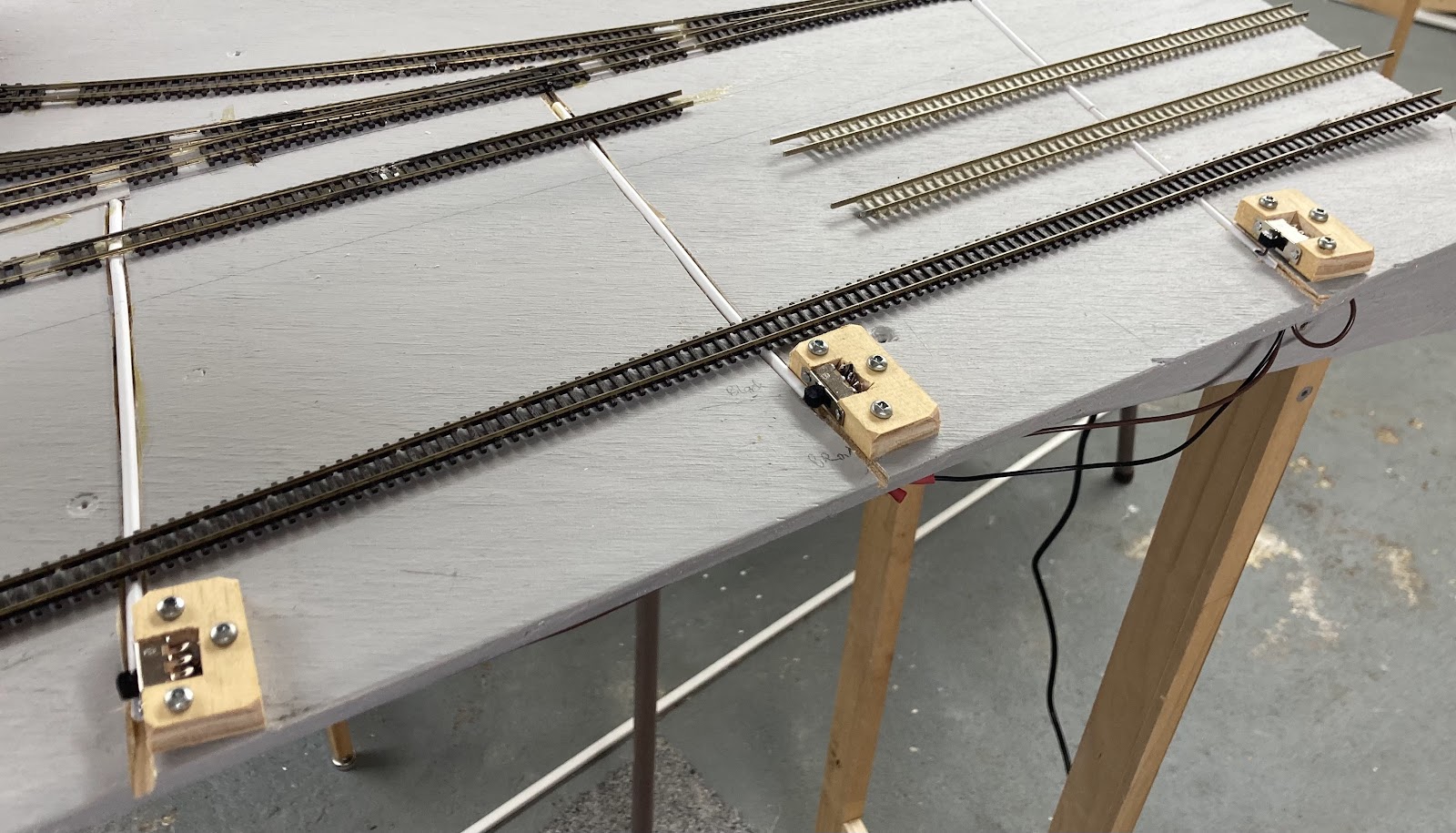

So this is the current thinking, which is fairly fluid, but it hasn't changed too much since it was first laid out in March onto a triangley bit of ply.

That ply baseboard is an offcut from Elmer Lane, and it has been braced with some bits of secondhand wood that live in the garage.