DB rolls on, since the miserable summer weather continued on Sunday:

The first thing I remembered to do on Sunday was to cut some channels for my overscale point rodding actuators. This was done with a power saw, believe it or not. With several cardboard boxes as barriers and some plastic sheeting on top of that (and everywhere else) only a few little patches of sawdust had to be vacuumed up.

I then spent a few hours powerfrogging the three points I needed for Elmer Lane, and did the three I needed for Studholme at the same time.

So with that, the rest of the depot trackwork went in pretty quickly. The curved point at the railcar depot will stay as an unmodified Peco.

I didn't have a lot of spare time on Monday and Tuesday, but did manage to solder (my most hated task) a few dozen wires down to power all the depot tracks other than some the roundhouse fan tracks.

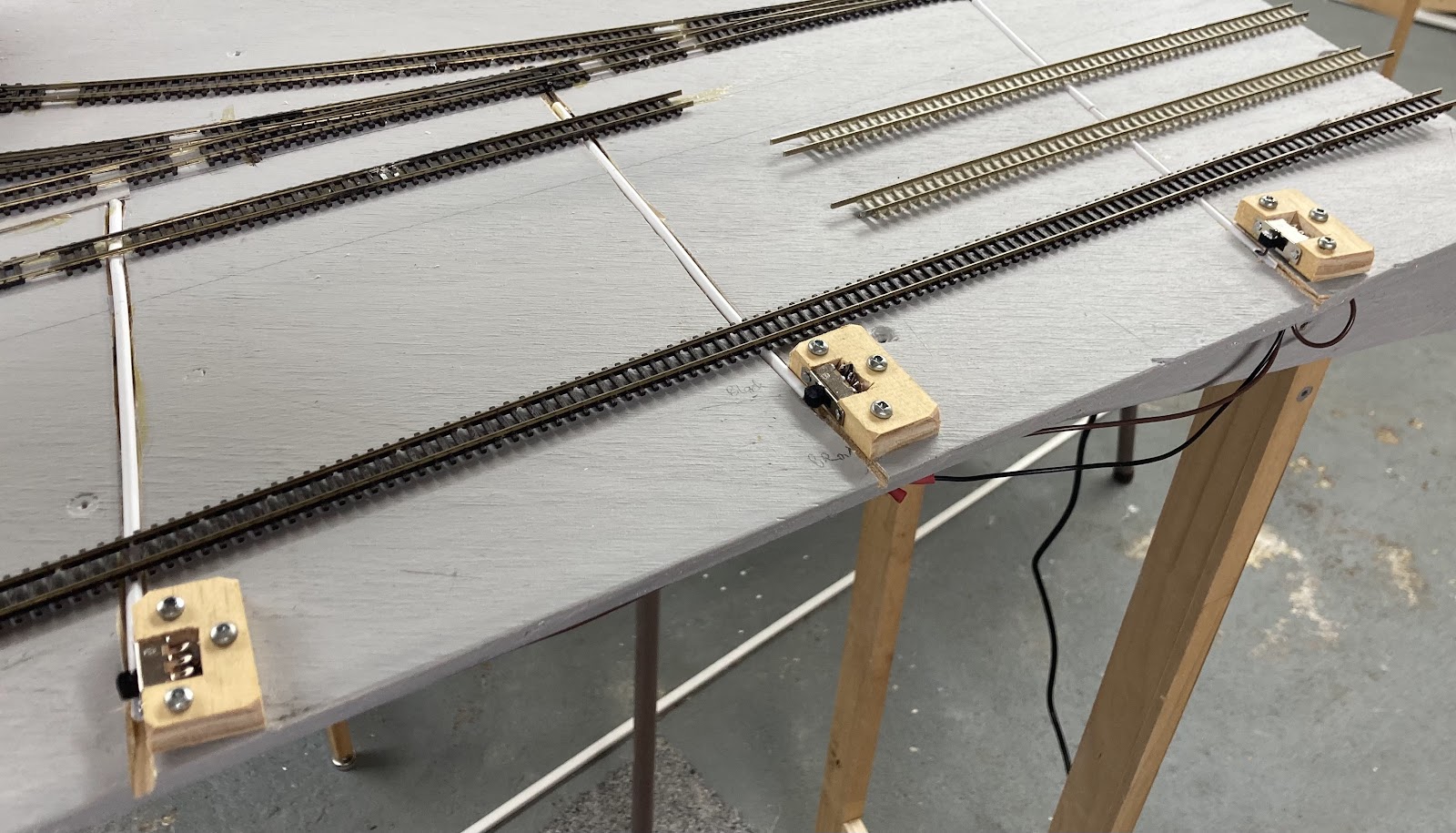

I also needed to route power to the DCC-froged points with a switch that also moves the points with a wire rod. One of the problems I had with Studholme was getting the alignment right so the switch throws the points. It was easy enough cutting holes in foamboard, but I thought cutting rectangles in plywood without upsetting the screw hole for the switch about 1mm away was asking for trouble.

So I decided to try mounting them sideways in a thin bit of wood. Cut out slot with razor saw, nail in switch (I did this at an angle for some clever reason I can't remember), cut off section of wood, drill holes for mounting screws (so you don't split the wood).

Solder on the three wires, line everything up, and screw it all down. Use those flat headed screws to minimise chances of splitting the wood.

Reasonably tidy, and at least they are completely functional, and they feel oddly ergonomic.

3 comments:

Are you going to display your modules at the Chch show?

It may be a year too early if I only have a balloon loop and a few modules done. Unless I could plug into yours, but that would require a siding coming off the edge of yours!

We have considered and planned how to make an 'exit' module. Just need a reason to do it.

Post a Comment