DB says.

Just looking behind the curtain at the blog now, there seem to be half a dozen little partially-finished posts of works in progress. I've also been distracted by life, and models in 5 separate scales, but many of those half-finished bits are mine. And I swore I'd never become a rubber-gauger...

So in the face of that, why not start another post on something completely different.

I've always loved Z ventilated vans. These were the long 50 foot white 3-door wooden ones with louvres, rather than the non-ventilated ones that were usually red oxide, or in the 70s/80s sporting various colours carrying parcels on our passenger trains).

They were quite popular at Studholme in the old days I'm told, carrying strawberries and other produce away. I recently read in a book of local history that they were usually marshalled next to the van at the back, so the guard could enjoy the smells!

Imagine my thrill when a pair of Trackgang examples came up on Trademe.

Now, if you've been reading MD for more than 10 years, I know what you're thinking, as I've had pretty mixed opinions of Pat Eade's old Trackside kits, but I came into this with an open mind, but with a bar that was set fairly low way back then.

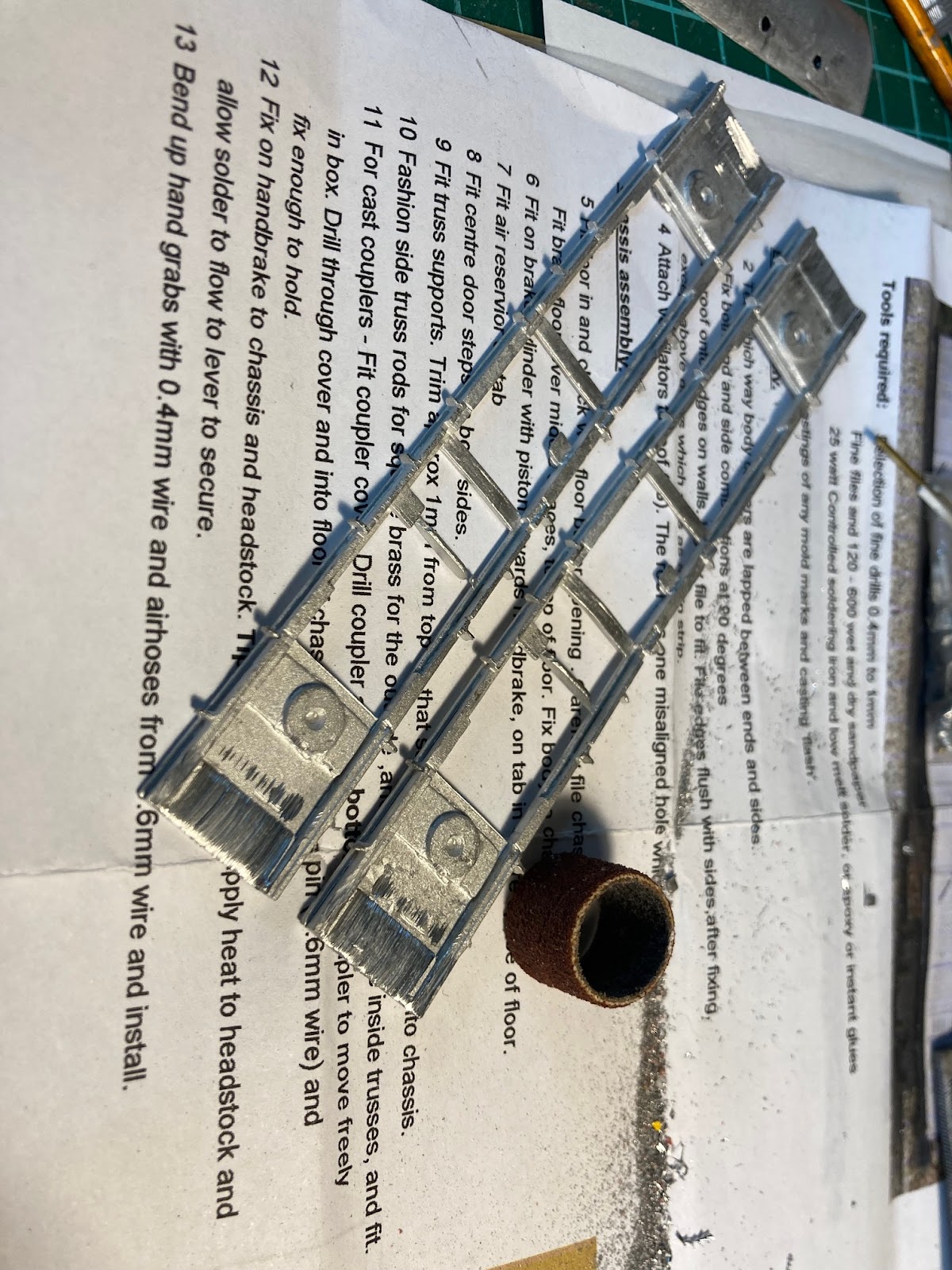

First impressions: Wow. the castings are impressive. Incredibly well detailed, clean, crisp straight lines, thin walled to keep the weight down. - far better than anything I've seen in NZ120 with the exception of the laser cut Batchelor Sheep Wagons. Certainly far more impressive than 3d printing seems capable of at the moment (there's a challenge thrown down!)

As for the bogies, one set was assembled (bonus! as these have always been a pain for me to do). They have pinpoint bearings! More on the bogies later when we get to them, but for now, let's start making things.

A quick whiz with a file cleaned up a few of the edges on the sides and ends, and things were straightened out and flattened after being in a mailing bag. But there was actually almost no flash to speak of. Just in case I wasn't clear, these are some really impressive parts in my fingers.

The only fiddling I did was to remove the coupler pockets with a Dremel drum, as I'll probably fit either MicroTrains or old Rapido ones. TBD.

You may remember from many earlier postings that I can't solder my way out of a balloon, so these were assembled with some random brand of super glue gel and strengthened with Araldite epoxy.Then it was time for the secret weapon to add some glue fillets inside to bolster the superglue:

Here is the roof going on. It required a fair bit of fling and bending to get it flat (well, "flat" to match the "almost-flat" metal box I had made). I drilled out the vent holes as suggested, but used a drill bit that was a little big. Which is silly, because I have the right sized one on my bench.The vents come three to a sprue (right side here of the pic below, seen both attached to the sprue and clipped off) and the little tails poke through the holes. Clever enough. Arguably the roof-plus-vents would be a nice 3d printed addition here to eliminate this relatively fiddly step. My clumsy fingers and failing eyesight proved the super glue gel's claim that your fingers wouldn't be instantly stuck to things to be only partially correct. Not instantly... A 3d printed piece would also reduce overall weight and move the centre of gravity lower. I did consider using some bent plasticard, but that would have left me with one nice edge, one terribly rough fettled one, and vents all over the place.

More to come.

1 comment:

50Ft Z vans were certainly a big part of 1980s provincial trains

Post a Comment