In which DB attempts to catch up with himself:

So with the three Studholme Junction module frames completed in exquisitely-cut plywood, the next step was to put a top on them.

While I'm not wedded to the idea, the Fremo120 standard suggests a 3mm thin layer of wood be placed between the track and the 'base' as a solid subroadbed to provide at least a minimalist amount of scenery relief even if nothing else was attempted, such as is likely here on the vast flat plains of Studholmeland. No yawning gulches or tunnelled mountains here.

I still have bad memories from decades ago of MDF and chipboard turning into spongecake when water is applied, so I might not be able to face gluing the ballast down... But be that as it may, I headed down to the local Mitre 10. Only to find they don't carry 3mm MDF.

However there was a 1200x600 sheet of 3mm MDF next to some thicker MDFs. "How much is this 3mm sheet, its just what I need for my model railway and, there doesn't seem to be a SKU or barcode nearby?" The reply was "No, we don't stock 3mm, that's a bit of packer to protect the sizes we do stock during shipping. You can have that."

So, problem solved, and economically at that. Especially as this was listed at 1200mm long and my modules are ostensibly 1200mm long, and this might be wide enough to deck the 'north' and 'south' modules. This is because while the south module's track with the Foley's road crossing needs a bit 400mm wide, the the north module is just a few tracks wide.

I laid the tracks out for the south module on the MDF sheet and pencilled around things ...

...then got to work with a skillsaw and jigsaw, and was pleasantly surprised at how tidy it came out.

I used a mouse sander to bevel the top corners of the cuts to give some shape for the ballast/mini embankment profile (otherwise I would have a sharp edge to these raised pieces that might more obviously show through the ballast... plus it gave me a chance to straighten out any imperfections). I did the same thing with more gusto to provide a little camber on the top of Foley's Road.

The MDF was then glued in place on the frame and weighted down. This is the 'south' module again in the pic below, the single track from the south coming in from the right, crossing Foley's Road (the 'T' running from side to side) and then expanding into loops either side of the mainline etc etc. Under the bright purple bottle centre-bottom you can see the trackbed for the Waimate Branch curving away from the island platform:

With two cross pieces of ply in the frame underneath, I thought the MDF would be strong enough on its lonesome. It is on the wide (more fully decked) areas, but under that single thin bit of mainline (and any other bits that seemed to move under an applied finger) I glued a stiffening piece of scrap thin wood underneath (I know N scale mechs don't weigh anything near the weight of a finger with me leaning on it, but better safe than sorry):

I filled the holes with spare foamboard. These sit at the height of the frame, 3mm below the trackbed, and this will all be painted and covered in scenery representing farm fields later. Second awesome purchase this month was a builder's 90 degree square thingy. What a great device for all sorts of things (including as a straight edge to cut foamboard rectangles.

The centre 'station' module, with the station, goods shed and several sidings out both sides, will be almost fully decked, so I will have to go see if I can locate another packing piece in another Mitre 10 wood bin and then go and find that helpful staff member again with my lost and bewildered face on...

Apparently the two 1200mm's referred to earlier on the 'south' end module were not quite the same length, so I will need a thin strip of MDF (or more likely stripwood) as a filler at the inboard end. I don't think this will be a problem at all. For the 'north' end module, I learned my lesson and buzzed the MDF in half at an unimportant place (not under any points or rail joints but on top of a piece of ply), so I could push the MDF right out to the endplate edges of the module. In the pic below, the end closest is being glued, and the bit at the top is just sitting randomly, awaiting its turn to be moved in and glued down. This is where the mainline from the north splits into the loop, and then two points spawn the island platform loop and the goods shed/loading bank loop, with those four tracks running towards centre 'station' module. The small gap between these two halves of MDF will be filled with a bit of balsa or even ballast later.

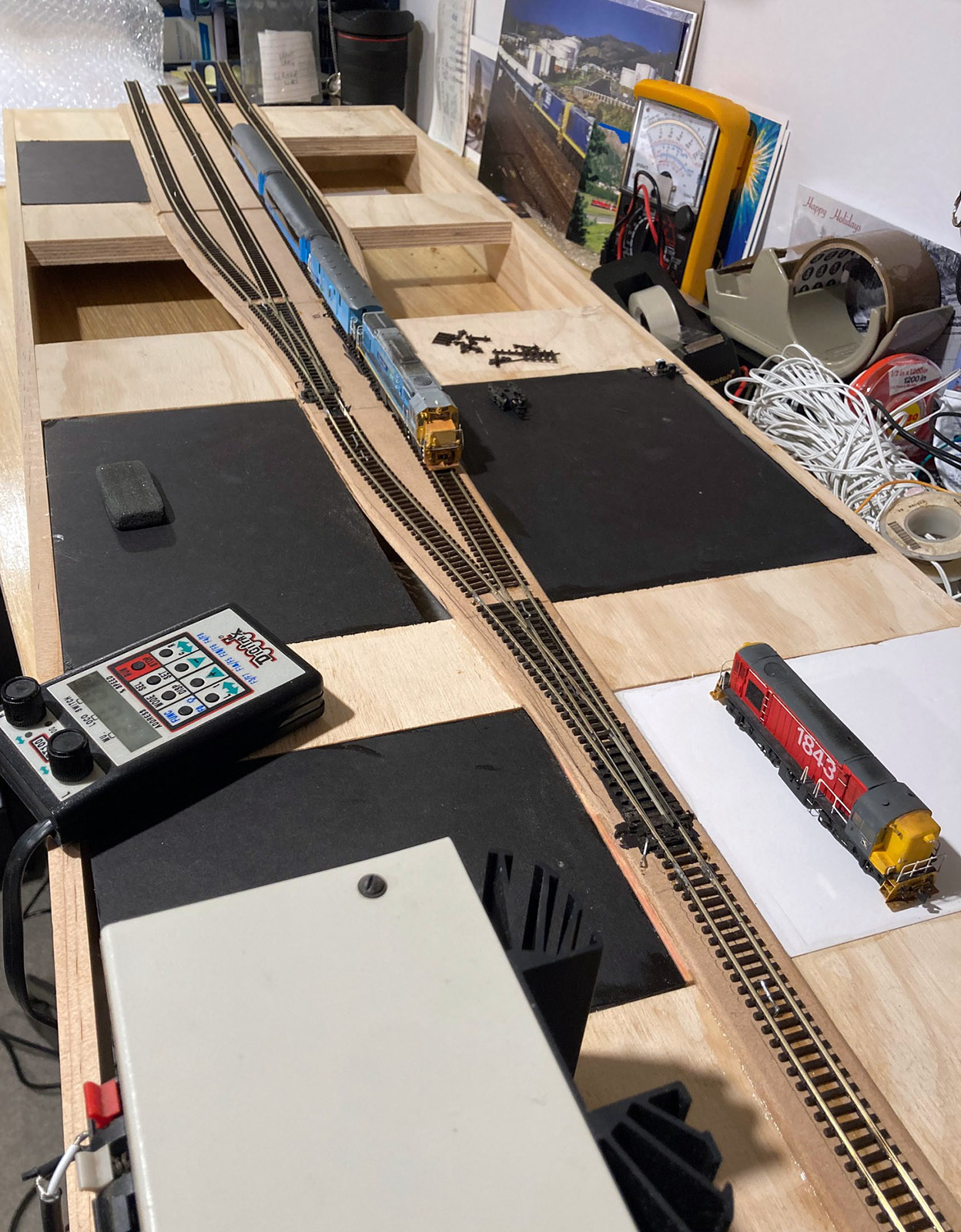

In the pic below, the three Studholme modules meet for the first time. Why hello there. The centre station module still yet to be decked, several weeks after these pics were taken!