In which DB acquires a table saw.

I've always wanted such a weapon, and there have been a few outstanding jobs around the house for a few years that could use a bit more precision... but who of the hack-carpenters amongst us can justify spending a grand on such a luxury. So when Mitre 10 had a Black and Decker one on sale (including legs) for $299 recently, I snuck out and got one.

Which is a good job, as I didn't really know how else I was going to cut up bits of wood into modules now that I'm in the mood to make something. And I've already ticked off some of those outstanding projects around the house too.

Mr Druff warned against using the old, warped, treated plywood in my stash, but our local hardware stores don't stock 18mm ply. After a few weeks of anxious pondering I found myself at Bunnings in Dunedin and picked up a small sheet of 18mm that fitted in the boot of the car, along with a few other little pieces of microlumber.

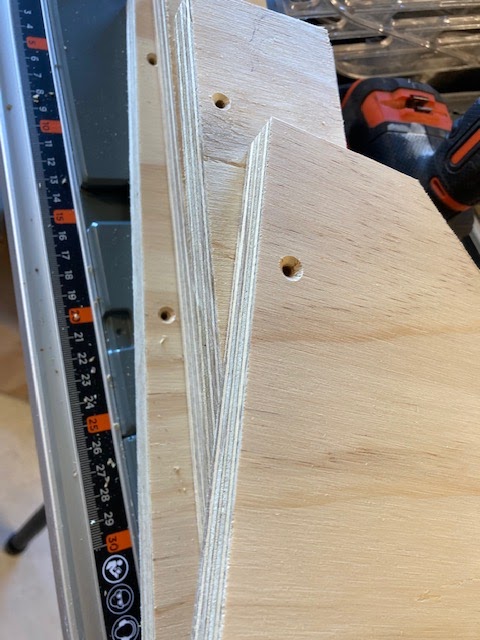

After another anxious week, I mustered the courage to try out the saw on the plywood. Wow. What a revelation. So easy. Square, flat, strong, straight, consistently sized and uniformly rectangular module pieces. the 'spacers and ends' are 38cm wide, plus two 1cm sides to make 40cm wide modules.

Glued together with some proper wood glue (I normally use the stuff from the $2 store that falls apart after a few minutes. This post not sponsored by Selleys wood glue.

And with countersunk screws. Mr Birch, our well-named woodwork teacher would have been impressed. And surprised.

Crikey, that almost looks the part. It's light, its a proper rectangle, it's flat and it's not torsionally twisty. And the top is yet to go on. Seen here with the top down on a flat bit of concrete while the glue sets.

The observant among you will note that this is slightly unorthodox in shape. It has a 10cm deep endplate where it will mate to other peoples' modules, but 6cm deep side sills. This is because Bunnings happened to have 6cm x 1cm pieces of wood that were 1.2m long and really straight. So I figured that would work well with minimal effort. After all, you can do what you like in the middle as long as your module (or module set in this case) mates up at the ends with the holes in the right places. I'm not sure the end plates really need to be 10cm deep, but I suppose I should adhere to at least one of the rules. In between my three modules, I am not, instead using 6cm deep endplates cut from the 18mm thick ply. Rebel without a cause.

3 comments:

Still have a full collection of fingers and thumbs?

As good as lazer-cut.

Great start

Post a Comment