Yesterday I spent a pleasant afternoon sitting at a desk while the sun shone outside completing the S scale crossover that I have been working on (I think its sort of like detention but while getting feed and with cups of tea). Unlike previous work sessions, I remembered the digital camera and so can now shed some light on this dark art.

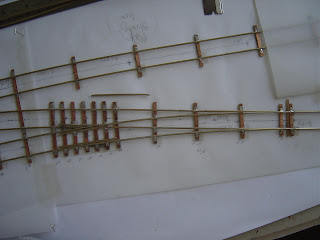

Here's where I got up to previously.

The 2 outside rails have been filed where the point blades come in to contact and the throwbar end. The frog has also been positioned with the aid of various track gauges. Note that this is being built as a crossover unit and all the other rails have been soldered into place.

Here is a close up of the frog area. Things to note are that one should not solder all the sleepers at this point as you may/will have to make adjustments later.

Here is the second point where I have shaped and installed the point blades. Note that these are one piece including the wing rails. It takes a bit of careful measurement to get it all right. The ends are created by cutting through the rail web (the bit at the bottom) on both sides at the correct spot and then carefully bending in a vice to get the correct angle. Also one of the check rails on the outside has also been positioned. To solder these in I used a 'dodge' that a local modeler has come up with. Make a piece of brass about 40mm long that is the correct width for the flangeways (NMRA standard). To solder the guard/check rails into place just drop this into position and push the guard rail up next to it. then just solder the guard rail into place. Its a piece of cake.

Here's the frog end of the point with everything soldered in. At this point the fun really starts as you get to run a wagon through to see if there are any tight spots etc. On one point it revealed that the guard rails were quite tight even though the back to back and there was a fair bit of bumping at the nose of the frog. Further investigation revealed that the wagon I had been using had old English finescale wheels from about 30 years ago. A switch to a wagon with North yard wheels then showed that all the problems were with the 1st wagon (I may have had to move the outer running rail in a wee bit, but this was not too hard).

Making the throwbar. 2 0.6mm holes have to be drilled 14.25-14.5mm apart. this made my inner finescaler quite happy, but the rest of me rather worried. The holes were drilled with a pin vise, with a drill selected with a micrometer from the many on offer. They were expanded slightly at the bottom to allow the pins that are to be soldered onto the point blades in. These are then bent to shape over a razor blade and cut short.

The whole thing installed and working. This is a fiddly job. First the web needs to be filed out so that the pin can lie flat against the rail. Then with a minimum of flux solder the pins to the inside of the point blade. I cut out a thin piece of paper and inserted it into the gap between the point blades and the throwbar ad this seemed to work well (ie I didn't solder it solid). Check again with a wagon to see if it all works OK.

I'm not waiting on my order of track and sleepers from Woodworks to see if I can step it up and scale it down. I think that the coarser clearances will make life a bit easier for me. The inner finescale is very excited to the point (haha) where I'm going to have to calm him down with the application of high strength beer I think.

2 comments:

Frankly, I'm disappointed....I would have gone with "En Pointe" myself...

Spent yesterday afternoon making a tool for machining the grooves in your roller track gauge.... not 100% successful, but I now have a track gauge of which I am not entirely ashamed, and it will go in the post to you tomorrow.... just need to true up the tool bit so I can get a neater finish.

Post a Comment